How is Artificial intelligence used in Manufacturing?

AI in Manufacturing with InfiVR’s Immersive Solutions

Top use case of artificial intelligence in manufacturing?

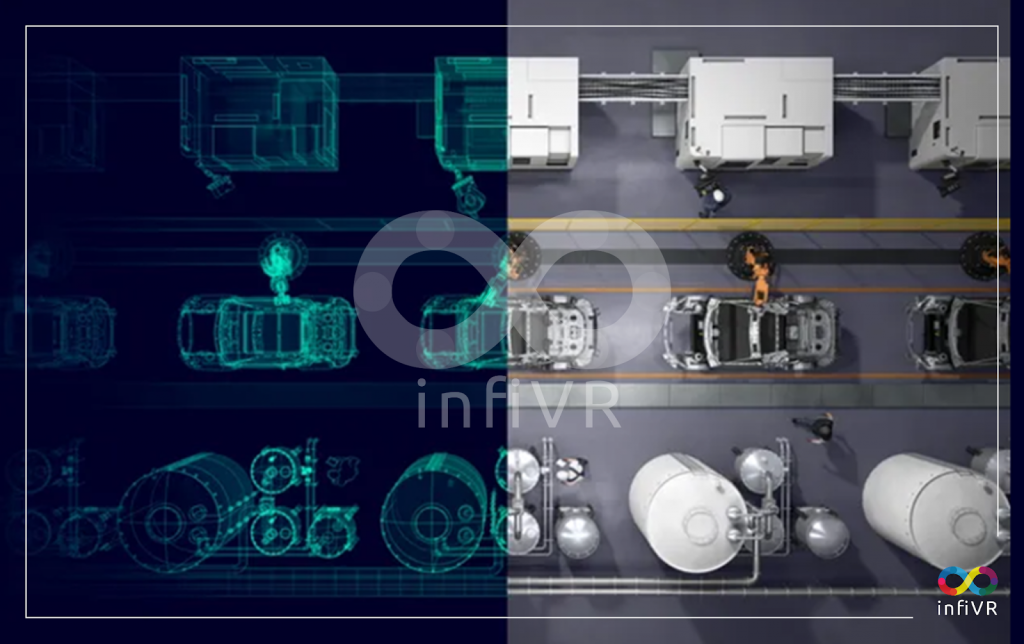

Imagine a manufacturing unit which is not only automated but intelligent enough where each machine, process and operator is connected and continuously learning. With Advanced AI, Metaverse, AR , VR and Spatial computing, manufacturers are entering into a future where efficiency, quality and flexibility are optimised in real time.

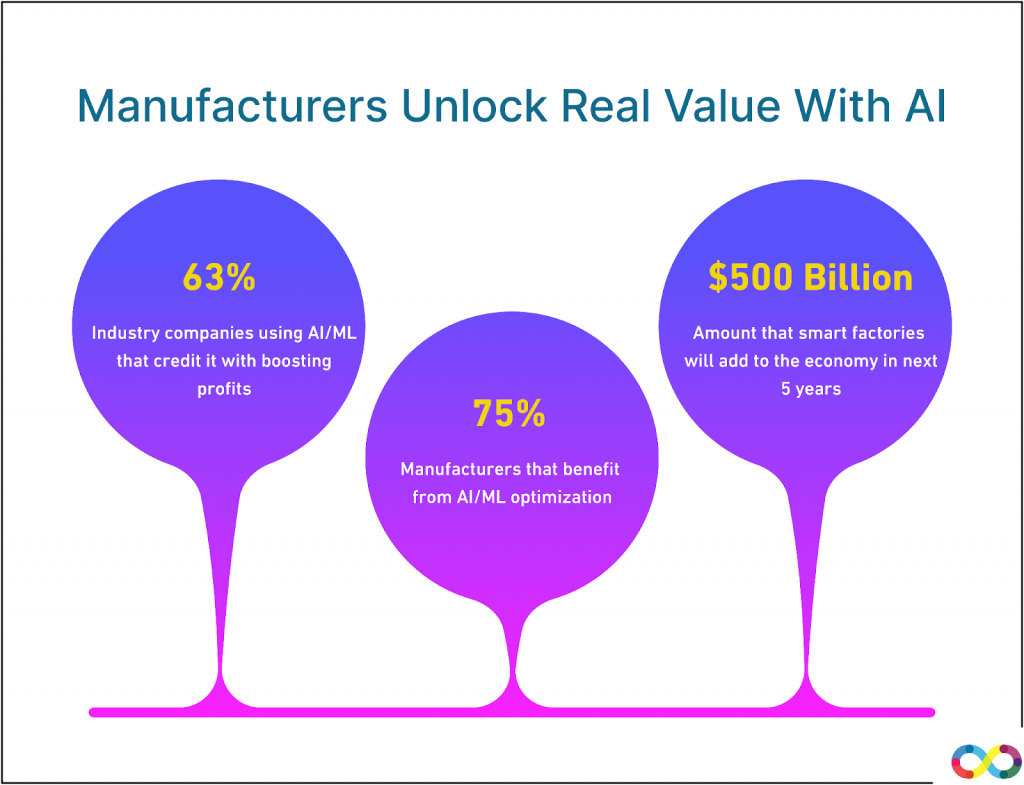

Potential of AI in Manufacturing Market

In today’s world, AI plays a crucial role by enhancing data collection and interpret it across different manufacturing environments. Every device, sensor and machine generates a continuous stream of data. AI algorithms use these data streams and perform optimizations which improve operations, safety, and reduce waste.

A recent report shows that AI adoption in manufacturing has increased from 14% to 34% in an year.

Let’s discuss few practical examples of AI in manufacturing:

Material Discovery and Customization

Usage of GenAI enhances the way how new materials can be simulated by analyzing their properties and molecular structures. AI helps build millions upon millions of atomic combinations while testing their features to find heat-resistant, flexible and conductive traits.

As an example, In aerospace, businesses are creating AI-created alloys that have the ability to withstand extreme temperatures which will increase the longevity of components used in aircraft.

Even in packaging industry as well, generative models can characterize fully biodegradable materials that decompose without losing resilience. Thus allowing manufacturers to manufacture environment friendly product and protect landfills in a relatively short time span, without going through tedious R&D or development phase.

Automated Quality Inspection

InfiVR is leading AI-Powered digitization and smart inspection for prominent organizations such as Volkswagen, Saudi Aramco, HAL, and others to leverage the power of state-of-the-art automation. With AI, XR, and machine learning integration, InfiVR empowers these businesses to significantly minimize costs, make operations efficient, and maximize process efficiency.

One of the innovations is AI-powered quality inspection systems, which utilize machine learning and computer vision to inspect product images in real-time and detect defects that may escape human inspectors’ eyes. For example:-

- Semiconductor Industry: AI systems identify micro-scratches, impurities, or irregularities on silicon wafers with increased precision and less defect.

- Automotive Sector: Multi-sensor AI inspection examines engine parts, scanning for internal defects or structural irregularities not visible to the human eye, avoiding defects from entering the market.

- Advanced Quality Tests: Certain AI systems use inputs from X-rays, infrared, and high-definition cameras to make in-depth quality tests, only allowing defect-free products to go out to consumers.

By adopting these AI-based solutions, InfiVR enables businesses to detect defects early, reduce product recalls, and enhance manufacturing efficiency, making their operations smarter, quicker, and less expensive.

Demand Forecasting in Supply Chain

AI can analyze large datasets to forecast demand more accurately, helping manufacturers anticipate market fluctuations. Using AR dashboards, managers can monitor inventory levels, stock-outs and deliverables, all within single platform.

GenAI could create synthetic data that models complex, large-scale supply chain disruptions. This simulation helps in predicting various “what if” scenarios, such as geopolitical issues, material shortages, or sudden demand spikes, allowing manufacturers to build more resilient supply chains with better contingency plans.

Hyper-Realistic Training Simulations

For industries such as chemical or heavy machinery manufacturing, AR and VR simulate high-risk scenarios (e.g., chemical spills, equipment malfunctions). Spatial computing enhances this by mapping real-world spatial layouts, allowing trainees to practice responses, evacuation procedures, or emergency repairs in a safe, virtual format. For e.g. in chemical industries, such trainings and simulations prepare workers for real world risks and potential hazards.

Hyper-realistic simulations also train technicians to perform maintenance operations by demonstrating exactly where to look for faults and fix parts in intricate systems. AR overlays offer real-time instruction as they lead through virtual models of engines, factory floors, or specialized equipment, greatly improving problem-solving ability.

InfiVR is leading this revolution, providing AI-Powered training solutions to industry giants such as SKF, Carl Zeiss, and more. Through the combination of AI and XR technologies, InfiVR is transforming workforce training into an immersive, experiential learning process that is significantly more effective than traditional methods. This innovative process helps employees acquire practical skills quicker, with greater accuracy and retention, ultimately boosting efficiency and productivity in industries.

AI can analyze each worker’s performance within these VR and AR simulations to tailor future training. For instance, a trainee who struggles with a particular machine component might receive additional practice scenarios focused on that area, creating a customized learning experience that accelerates skill development.

Some use cases of how major manufacturing companies are leveraging AI to enhance operations, improve productivity, and reduce costs.

1. General Motors (GM): Predictive Maintenance

GM uses AI for predictive maintenance in its manufacturing plants. By analyzing data from IoT sensors on machinery, AI predicts equipment failures before they happen. This reduces downtime and optimizes production schedules.

Impact:

- Reduced unexpected downtime by 15-20%.

- Saved millions of dollars annually by minimizing machine failures.

- Improved overall equipment efficiency (OEE) by integrating AI systems with legacy machinery.

2. BMW: Quality Control with Computer Vision

BMW implemented AI-driven computer vision systems to inspect car parts for defects during assembly. AI scans components and compares them to digital blueprints for quality assurance.

Impact:

- Increased defect detection rate by 30%.

- Reduced production line inspection time by 50%.

- Lowered warranty claims due to better product quality.

BMW’s adoption of AI across manufacturing operations saved approximately $15 million in quality control costs annually.

3. Siemens: AI-Powered Digital Twins

Siemens employs digital twin technology powered by AI to simulate production lines, test workflows, and predict operational bottlenecks. These AI models enable optimization before actual deployment.

Impact:

- Reduced time to market by 20%.

- Improved production efficiency by 25%.

- Enabled simulations of over 1,000 design iterations within hours.

4. Tesla: Robotics and AI in Assembly Lines

Tesla uses AI-powered robotics for automation in its Gigafactories. From battery production to car assembly, AI enhances precision, reduces waste, and optimizes energy consumption.

Impact:

- Reduced production waste by 30%.

- Achieved a record production of over 1.3 million vehicles in 2022, a 40% increase from 2021.

- Improved energy efficiency by 20% in factory operations.

5. Procter & Gamble (P&G): AI in Process Optimization

P&G implemented AI to optimize manufacturing processes, such as chemical mixing and packaging. AI models predict the ideal conditions for maximum yield and minimum waste.

Impact:

- Reduced material waste by 10-15%.

- Improved production efficiency by 12%.

- Estimated cost savings of over $1 billion in operational efficiencies.

InfiVR’s Impact on AI in Manufacturing Industry

InfiVR’s immersive technology brings AI insights to life. With virtual twins (digital versions of real factories), workers can explore a factory floor virtually, identifying bottlenecks or potential issues in a safe, simulated environment. New workers can practice safely using AR headsets, while VR lets teams experiment with different factory layouts.

60% percent of manufacturers now depend on AI to support their daily operations. The path forward is bright with smarter AI driving manufacturing shaping a resilient future.

Are you ready to bring AI into your manufacturing unit? Feel free to contact InfiVR at hello@infivr.com