AR and AI in Oil and Gas

In an ordinary day, when the technicians are operating intricate machinery in everyday changing weather conditions. In remote, hostile, and unforgiving oil and gas environments, every second is critical. This is exactly how and why AR which is fully AI-powered- powered takes over to fundamentally change the digital transformation landscape in oil and gas.

The long-term potential of AI-Powered 3D Immersive Solutions includes the visualisation of hazards alongside real-world devices and the provision of sensor data. This aids in step-by-step instructions. This digital-physical fusion is proving invaluable for energy businesses in changing maintenance, training, safety, and engineering workflows for the better.

Steps of AR Usage in Aid of Maintenance and Parade of Equipment Inspection.

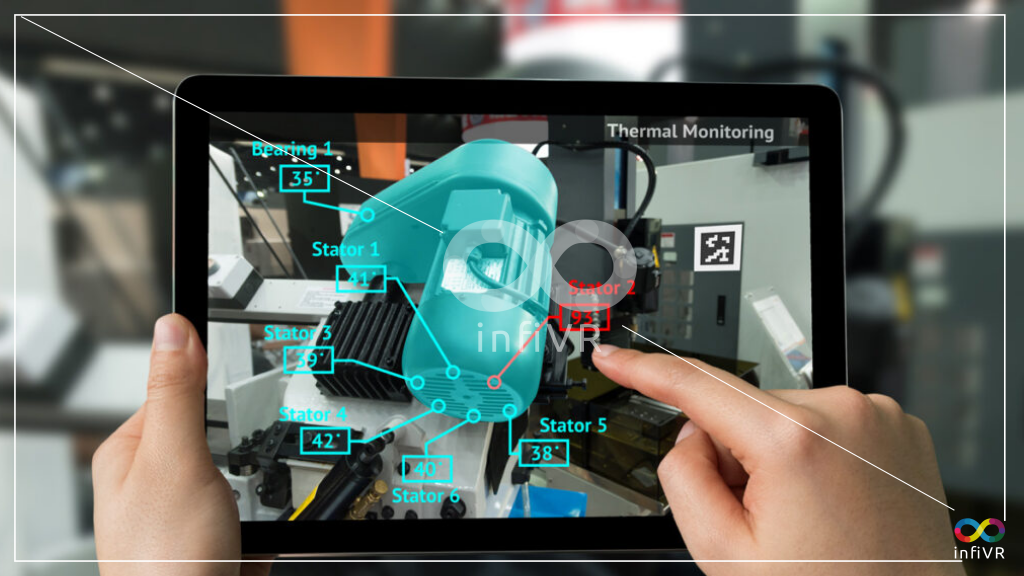

The days of using a logbook and an expert to service complicated machinery are long gone . Telephone support and AI-powered Augmented Reality Smart Glasses are catalysts in changing these services for the better. Now, having a put on a Smart Glasses,the technician can view step-by-step instructions, animations, and live sensor data indeed in real time.

Rather than halting work to consult a man for assistance, they receive critical data such as pressure readings, valve positions, or torque values through displays located within their line of sight. This fully optimises their workflows to be faster, more precise, and fully hands-free.

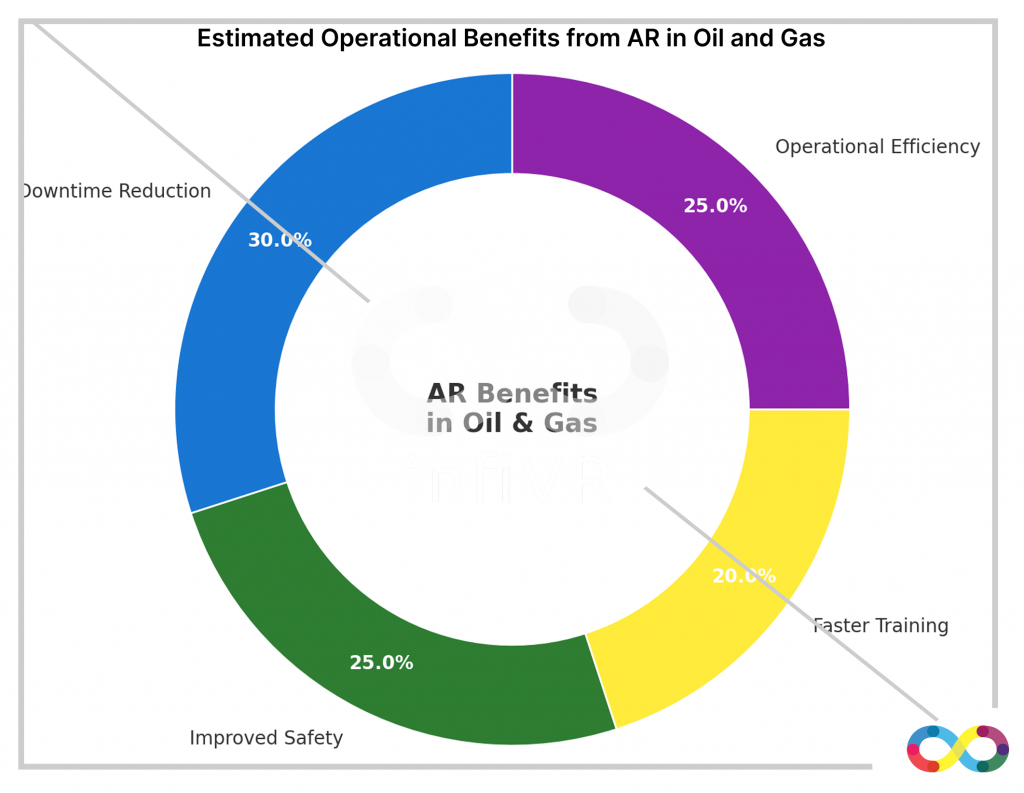

As Global Data indicates,in it’s recent report digital transformation associated with AR technology enables person to function more productively while reducing costs. Efficient use of Digital Transformation, as noted by McKinsey. Also, AR technology can reduce operational expenditures by as much as 25% per barrel. This results in underscoring its significance in business innovation.

Academic research supports these findings. Eversberg and Lambrecht conducted a comparative study of AR-based and paper-based instructions and reported marked improvements in productivity and efficiency. Technicians reported completing work 21% faster and feeling 26% eased mentally. Similarly, Nagy and others employing the NASA Task Load Index to AR rated systems reported significant reductions in workload and enhanced decision-making assistance.

Specialisation in the Cloud: Off-Site Assistance Using AR Technologies

On location there are my specific oil fields or oil platforms, specialists who are not regularly present. Augmented Reality solutions could assist. Using AR glasses, the field technician can “stream” their sight to specialists who are not on location. These specialists can provide instructions, draw, or highlight critical things in real time in the augmented reality interface.

This method is called “see-what-I-see”and facilitates hands-free interactive operator assistance. As a result, there is no need for lengthy telephone explanations. Travel is eliminated, and it repairs are done faster, also the chances of making a mistake are low. Many businesses have reported faster problem resolution, improved accuracy, and reduced errors due to augmented reality-enabled remote assistance.

Enhancing AI in Oil and Gas Industry Operations with Augmented Reality

AI powered Augmented Reality (AR) is revolutionising the oil and gas industry by optimising the management of physical assets across their entire life cycle. AR technology makes the design, installation, operation, and , inoperative enhancing efficiency and reducing errors.

Projects in oil refineries which are in large scale that engineers often face issues in accurately predicting complex layouts during the design phase. AR solves this problem by giving engineers to overlay 3D equipment models onto real-world locations. This enables them to visualise the given layout in real scale, finding potential design clashes early and making it more and mere cost-effective method.

InfiVR’s AR solutions help teams visualise equipment placement and structural changes directly on-site, reducing guesswork and avoiding delays especially in confined or high-risk areas. We offer AI-powered immersive VR/AR training solutions already trusted by companies like ExxonMobil, Shell, and BP. Our modules cover key safety and operational areas in oil and gas, helping improve compliance, reduce incidents, and deliver real ROI across VR headsets, desktop, and web platforms.

We offer ready-to-use modules such as Confined Space Safety Training, H2S Gas Leak Response Simulation, Lockout-Tagout (LOTO) Procedure Training, Permit to Work (PTW) Simulation, Fire Safety and Emergency Evacuation in Refineries, Rig Floor Operations & Safety Walkthroughs, and many more.

Operational that looks into Enhancements

Once they are installed AI-powered AR provides better operational oversight by allowing technicians to scan equipment and access historical data, sensor readings, and real-time acts prominently and quick. This instant access to information helps in identifying irregularities or trends promptly, increasing maintenance efficiency.

InfiVR’s platform makes it smooth and integrates with the existing systems like CMMS or asset management tools. This ensures that data which is collected during inspections is directly inserted on to the company’s central database. Real-time visibility into asset performance enables more accurate planning for maintenance schedules, reducing unexpected breakdowns and enhancing uptime.

AR also plays a crucial role in ensuring safety during decommissioning and shutdown operations by projecting disassembly steps and environmental protocols to guide workers effectively. By providing visual guidance, AR minimises reliance on memory and reduces the risk of errors during critical operations.

Improving Collaboration

Much ahead the AI-powered AR fosters collaboration among engineers, safety officers, and operations managers by enabling them to access live data, annotations, and overlays simultaneously and regardless of their location. This collaboration perspective increases coordination and expedites decision-making processes, specially in situations requiring rapid responses.

AI and Augmented Reality has made its role as a leader visual aid in the oil and gas industry. It has now developed into a important tool for constructing safer, smarter, and more efficient infrastructure within this sector.

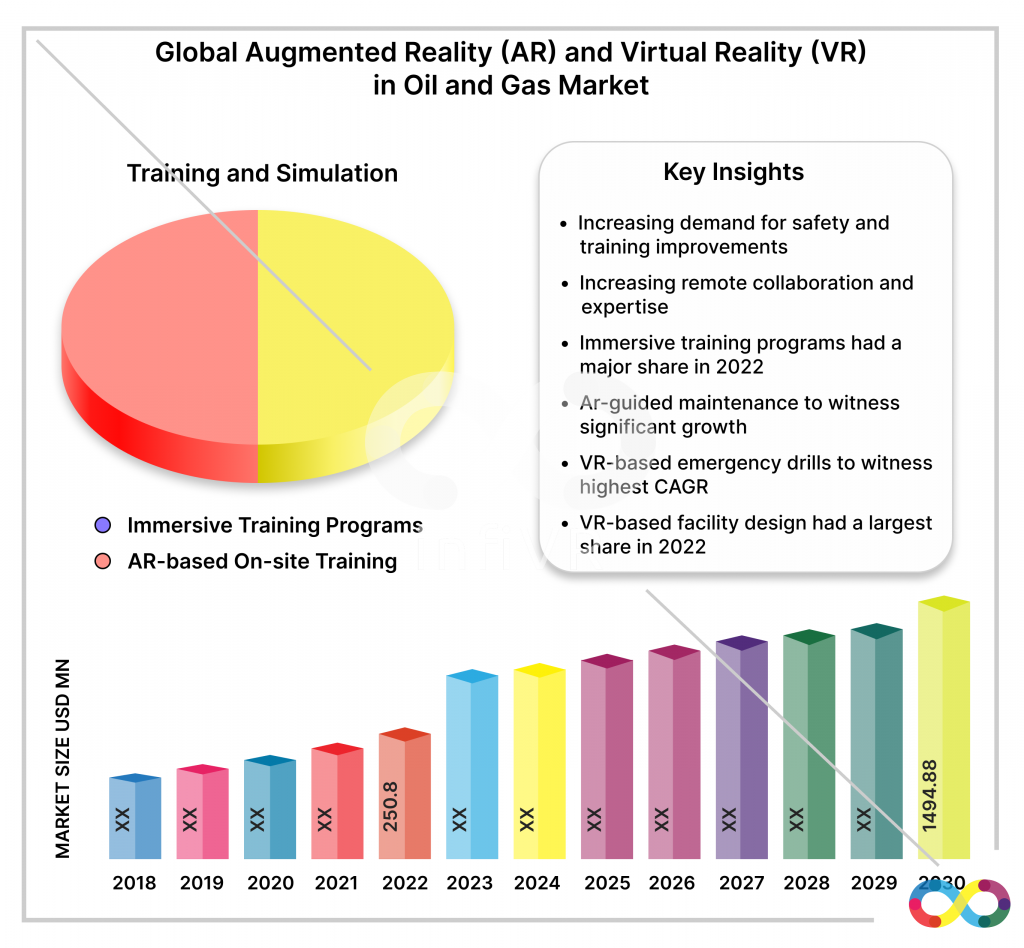

Practical Training in a Simulated Environment

Training oil and gas workers is time-consuming, hazardous, and expensive. The general industry practices in classroom education usually fails to equip trainees for actual field work. Augmented Reality makes it easier to training by allowing new technicians to practice on real equipment, accompanied by digital instructions and overlays.

Trainees are guided to follow every step of the process. This performance is evaluated in real time, meaning they can attempt as many times as they wish without affecting real operations. Research comparing AR training to other training methods found that subjects who trained with AR not only retained more information. But also reported a higher degree of self-confidence.

An Incident That Transformed Everything

The Piper Alpha platform in the North Sea suffered a series of explosions and fires on the 6th to the 7th of July 1988. This tragic incident resulted in the death of 167 people and the complete destruction of the rig within a few hours. This was due to a maintenance negligence of a hand-tightened blind flange after a safety valve was removed. The disaster was amplified by still-functioning backup pumps and disruption of communication—turning gas leaks into catastrophic modular explosions. Along the absence of gas control procedures and muted exhaust controls, effective evacuation was impossible

The Piper Alpha disaster resulted from a combination of more than just one problem. Also, maintenance, control, and hazard plan execution gaps unfilled by today’s technologies could have resulted in a different sequence of events. Tools available today, like AR and InfiVR’s AR/VR suite, serve with proper measuring technologies which could finally change the industry:

Multi-Factor Maintenance Protocols.

Maintenance and safety procedures done through AR would remove the need for hand written instructions, permits, and notes for wrap around equipment prompts to aid the personnel. This would mean. In high-risk sectors such as oil and gas, such a small mistake in maintenance can result into a catastrophe. Technicians typically rely on paper-based processes, print-based directions, or word-of-mouth explanations when performing complex tasks in all of which can result in misunderstandings or forgotten steps.

The expectations for accuracy, safety, and efficiency have always been high in the oil and gas industry. Except that with deteriorating infrastructure, dangerous environments and more regulation

InfiVR’s AI-powered AR Solutions in the Oil & Gas

With InfiVR’s AI-powered AR maintenance solution, technicians use smart glasses or tablets to view real-time instructions and sensor data directly on equipment minimising risks and human errors. We’ve created 250K+ AR/VR modules for the oil & gas industry, covering departments like HSE, QA/QC, inspection, and offshore operations to enhance training, safety, and efficiency.

On the horizon, there’s not much margin for error anymore. Solutions such as Augmented Reality, especially when delivered by InfiVR, have the potential to completely disrupt maintenance, training and safety thinking. Not only does AR streamline the process it also adds clarity where it’s most needed.

It may be expertly walking a technician through a valve replacement,rehearsing an emergency shutdown with a new hire. But in real-time, visualised support is a game changer for how teams operate. And that way ahead isn’t simply about joining the digital revolution. While it’s about integrating smarter tools into your everyday workflow. Solutions like InfiVR’s are demonstrating that can be the case and when complex working environments are combined with intuitive technology, teams move faster, and make fewer mistakes.

Interested in exploring how InfiVR’s AI Powered solutions in Oil & Gas can elevate your operations? Reach out to us at hello@infivr.com—our team at InfiVR would love to connect.