Boeing: Cuts 75% training time with VR & Increases accuracy by 33% using AR

Boeing is the world’s largest aerospace corporation, producing commercial jetliners, defence aircrafts, space, and security systems. Boeing is dedicated to being the industry leader in aviation and innovation by providing aircraft and facilities that are superior in terms of safety, design, and performance. Now as you can imagine, designing aircraft is one of the most complicated processes challenging engineering tasks with potentially disastrous consequences if something goes wrong. As a result, the building process must be handled with extreme caution, with room for no error. One of the most ??????? ?????? ?? ?????????? ??? ?????????? ?????????? ?????????? ??? ??????, since large stretches of wire connecting various sub-systems are spread out in the plane and must be connected precisely.

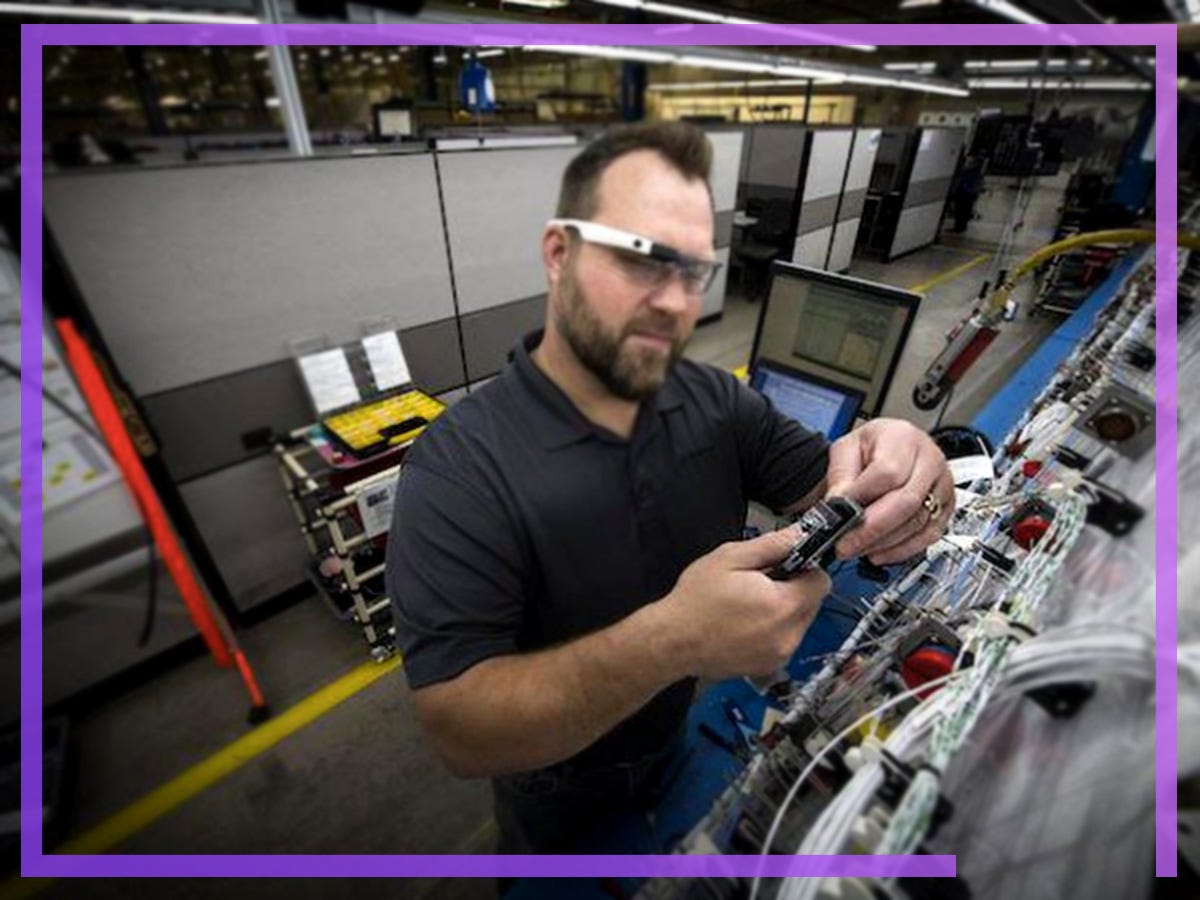

To overcome such issues Boeing has been using augmented reality to provide technicians with real-time, hands-free, immersive 3D wiring diagrams right in front of their eyes. Technicians use a HoloLens to guide the installation of wiring harnesses throughout the aircraft — replacing the “20-foot-long paper diagrams” previously used to complete the task. According to the company, this increased wiring speed and accuracy by 33%, saving millions per jet and allowing Boeing to manufacture more aircraft at a faster pace.

InfiVR is working with such leading aerospace and aircraft manufacturing companies to provide them augmented reality based solutions which assist technicians and associates in aircraft manufacturing processes like; riveting to electrical wirings to subassembly of systems for final assembly of aircraft which are few of the most complex stages of aircraft manufacturing.

Boeing is also using Virtual Reality for certain ???? ??????????? ????????????? ?????. While many employees receive training in aircraft assembly, some jobs are more ‘tribal.’ Like a cargo door seal that runs around the fuselage joint. It’s a 50-step procedure with just a handful of people in the business who know how to do it. Boeing incorporates virtual reality training by showing engineers the various pieces of equipment involved and how to bring them together using a detailed 3D model using the Microsoft HoloLens. As part of the experience, textual guidance appears, and the engineer is guided through the entire process by a voice-over. Boeing believes that by using this method, they have been able to reduce training time by 75% per person.

Boeing has incorporated AR/VR into its ????? ??????????? efforts. The Starliner, a small crew transport module for the International Space Station, is being developed with the HoloLens. Boeing’s application development lead in the space exploration IT division, Connie Miller, claims that “The HoloLens comes in handy here. We will examine the module closely to ensure that there is enough clearance and room to access the items you will need to repair.”

This helps spot issues earlier in the process, when the product is still being designed, rather than after it has been created, when fixing them is much more costly and time-consuming. Also, when astronauts prepare for crewed space missions, every step of the flight is practiced thousands of times. While it takes just 12 minutes to launch a spacecraft from zero to orbit, it takes years of planning and hundreds of hours of complex training simulations. For the mission to be successful, everything needs to go flawlessly. So, In Houston, Virtual Training applications were integrated with physical simulators. The team were able to use virtual reality simulators to execute all of the interactions, including voice and turn commands, while immersed in the same environment as if they were sitting in the actual spacecraft. This opened up unprecedented virtual reality training possibilities for a crewed space mission for the Boeing Starliner programme. We at

InfiVR are working with one of the renowned space and research organisations providing them virtual reality based simulation training for In-capsule experience space flight experience involving various stages like; launch, ingress, zero gravity experience, orbital experience, emergency situation and various other operational scenarios during the space flight.

InfiVR is working on a zero gravity VR simulator using various gimbal based zero gravity simulators.

Despite all these applications, virtual reality is still a relatively new idea in the business world, and its benefits must be sold to large corporate management teams. Although some businesses, such as Boeing, have early adopters and evangelists, others are unaware of the technology.

It will be critical for the aviation and aerospace industry to find the right solutions to keep up with training requirements as demand for new aircraft maintenance technicians rises over the next two decades. Course curriculums will need to be customised to allow for optimal learning, and Boeing claims that emerging virtual and mixed reality technology will be critical in enhancing student engagement, instructional efficiency, and information retention.

Above applications of augmented reality and virtual reality are just a tip of an iceberg, AR / VR will seamlessly become part of almost all stages of complex engineering in years to come.

InfiVR is pioneer in bringing about this transformation, and we love to help organisations who are forward looking to adopt technologies to make their processes efficient.